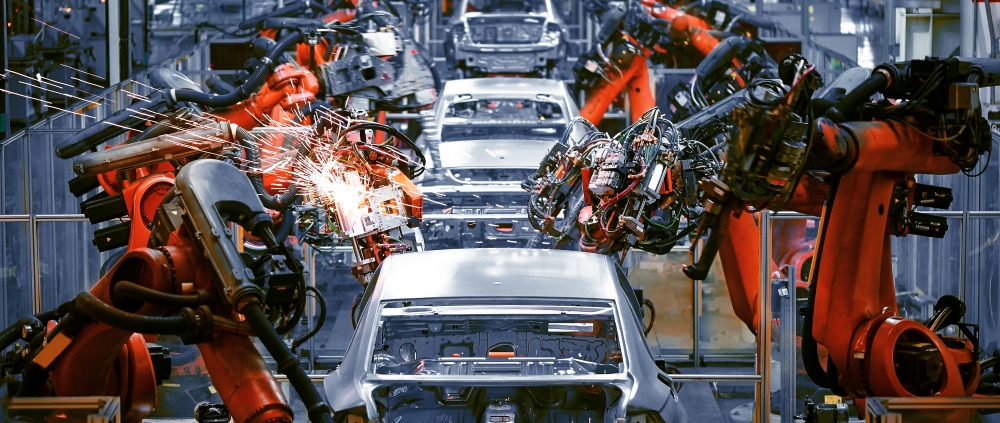

Innovation is ceaselessly advancing in the manufacturing business. With new improvements in automation, the industry is presenting the utilization of Robotics in Manufacturing working environment. Since the innovation is so unique, there are numerous worries that robots will take over manufacturing, leaving people without occupations and changing the business overall.

Even though the worries are substantial and change can be alarming, the presentation of Advanced Robotics for Manufacturing positively affects both manufacturing and the representatives.

There are numerous manners by which Industrial Robot Manufacturers influence The Key Areas of Your Business, including the formation of new, more mentally focused positions, the advancement of profitability, cost and time productivity, and even the progress of a greener workspace.

Here is a Closer Look at How Robotics in Manufacturing Impacting

Production of New and Better Jobs

As indicated by a 2014 review of U.S makers, the most significant effect of robots in the assembling business is that they will make new positions open doors for human specialists. Rather than moving significant parts or performing dreary assignments, laborers can figure out how to program and lead the machines’ maintenance.

As the Robotic Arm Manufacturers keep on developing next to each other, many new job opportunities are being made. Not exclusively are these kinds of occupations more attractive; however, they likewise remove human workers from conceivably dangerous circumstances.

Economic Gains

More business brings more cash. It’s a success for manufacturers and expands the intensity of the country. The ascent of robotization can be the way to working up American factories in the U.S. economy instead of sending work to another country. Manual bend welding, for instance, is a backbone of manufacturing that has profited from Robotic Arm Manufacturers. While it is less expensive to physically arc welding a little part in China, welding robotics has eliminated the need to do so. With improved quality and efficiency preserving U.S. plants, occupations are spared, and American producers can extend home activities.

Robotics in Manufacturing Save Money and Time

Robots originally began being utilized in the industry in the mid-1960s. From that point forward, they have made some fantastic progress. Robots would now be installed in less time and for less expense than in previous decades. Expanded sales have seen costs descended drastically. Built-in state-of-the-art offices, robots include quality improvements and managed security principles that mean investment funds on unscheduled downtime and labor costs. Robots can likewise work every day, all day, expanding production, limiting downtime.

Empower Adaptable Manufacturing

Buyers and users need more assortment. We need comfort, quality, and we need six distinct sizes in a single bundle. It’s astonishing what that does to the assembling mind when you should depend on more limited item runs. Particularly with the development of AI and self-learning robots, this is establishing a substantially more adaptable manufacturing climate. The advancement of the Industrial IoT, associated, coordinated, talking, and learning together, is driving this too. The declining cost of robots is empowering that in the marketplace, as will 5G networking abilities.

Options to Attract New Clients

Innovative advances can make new services, which can, thus, lead to new business openings.

Improve Safety

A robot could probably take over laborers doing repetitive tasks in manufacturing activity, improving work security. There are practical circumstances where it’s only more secure to depend on a robot, for example, in numerous picking, cuttings, pressings, and stacking apps.

Organizations presently have understood that robots and other manufacturing innovations offer golden occasions to improve profitability drastically. A sharp expansion in the utilization of automated frameworks would change how organizations assess their production and expansion plans. From accuracy machining and collecting to material handling, Advanced Robotics for Manufacturing has been making things more straightforward for producers worldwide. In North America and other created portions of the world, organizations like BP Automation have been giving economically feasible engineering solutions for many ventures. It is high time to open the next level of Technologies Shaping Businesses via automating your manufacturing processes.